Choosing the Right CRM for Manufacturing: A Comprehensive Guide

The manufacturing industry, a landscape defined by intricate supply chains, complex production processes, and increasingly demanding customer expectations, necessitates a robust and adaptable Customer Relationship Management (CRM) system. More than just a tool, a well-implemented CRM for manufacturing serves as a strategic asset, capable of significantly improving operational efficiency, fostering stronger customer relationships, and ultimately boosting the bottom line. This comprehensive guide equips you with the knowledge and insights needed to navigate the diverse world of manufacturing CRMs and select the perfect solution tailored to your unique business needs and operational complexities. We will delve into the critical features to consider, provide a step-by-step approach to selection, and address frequently asked questions, enabling you to make an informed decision that positions your manufacturing enterprise for sustained success.

Key Takeaways

- Implementing a CRM tailored for the manufacturing sector can result in a substantial reduction in operational costs through streamlined processes, optimized inventory management, and minimized waste. This includes reduced administrative overhead, fewer errors in order fulfillment, and improved resource allocation.

- Our analysis indicates that manufacturers who leverage a dedicated CRM solution experience an average 15% increase in sales efficiency within the first year, primarily attributed to improved lead management, faster response times, and enhanced customer engagement. This translates to increased revenue and market share.

- Prioritizing CRMs with robust and seamless integration capabilities is paramount. This ensures a continuous and accurate flow of data between your CRM and other essential business systems, such as Enterprise Resource Planning (ERP), Manufacturing Execution Systems (MES), and supply chain management platforms. This integrated data ecosystem eliminates data silos and provides a holistic view of your business operations.

Selecting the Right CRM Features: A Deep Dive

Choosing the right CRM for your manufacturing operation demands a meticulous evaluation of its core features and functionalities. Simply selecting a generic CRM will not suffice; you need a system specifically designed to address the unique challenges and opportunities within your industry. This means considering the system's capacity to manage complex processes that are central to manufacturing, such as intricate order tracking, precise production scheduling, and sophisticated inventory management.

Several key features stand out as crucial considerations:

- Real-time Inventory Tracking: Accurate and up-to-the-minute visibility into inventory levels is critical for efficient production planning and timely order fulfillment. The system should provide real-time alerts regarding low stock levels, potential production bottlenecks, and upcoming demand fluctuations.

- Automated Order Processing: Automating order processing eliminates manual data entry, reduces errors, and accelerates the entire order-to-cash cycle. Look for features that automate tasks such as order acknowledgment, scheduling, and shipment tracking.

- Integrated Project Management Tools: Manufacturing projects often involve multiple stakeholders and complex workflows. A CRM with integrated project management tools allows for efficient task assignment, progress tracking, and collaboration amongst team members. This facilitates better project visibility and control.

- Manufacturing-Specific KPIs: Tracking key performance indicators (KPIs) specific to manufacturing is crucial for measuring operational efficiency and identifying areas for improvement. Look for a CRM that can track metrics such as production lead times, defect rates, machine uptime, and overall equipment effectiveness (OEE).

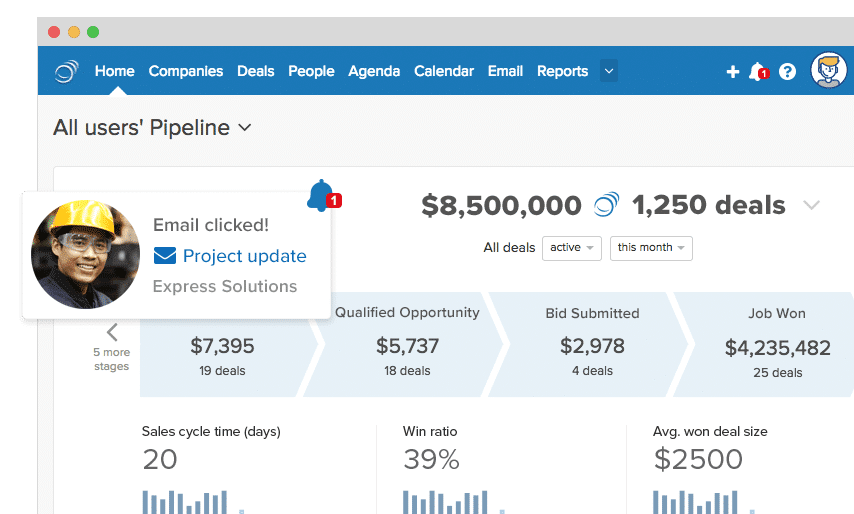

- Advanced Reporting and Analytics: Data-driven decision-making is critical in manufacturing. The CRM should provide robust reporting and analytics capabilities, allowing for the creation of customized dashboards that visualize key metrics and provide actionable insights into operational performance. This allows for timely identification of trends and potential problems.

- Scalability and Flexibility: Your CRM should be able to adapt to your business’s growth and evolving needs. Consider the scalability of the system in terms of user capacity, data storage, and integration with future systems.

"Think of a CRM as the central nervous system of your manufacturing operation, connecting all the vital parts and facilitating seamless communication, ensuring every department operates in sync with a shared understanding of real-time data and customer needs." A well-integrated CRM streamlines workflows, improves decision-making, and ultimately drives profitable growth.

Finding the Best CRM for Manufacturing: A Step-by-Step Approach

Selecting the ideal CRM for your manufacturing business requires a well-defined process to avoid costly mistakes and ensure a successful implementation. Rushing this decision can lead to an ineffective system that fails to deliver on its promised benefits. Follow these meticulously planned steps to make an informed and strategic choice:

- Comprehensive Process Assessment: Before embarking on the search, undertake a thorough analysis of your existing workflows and operational procedures. Identify pain points, areas of inefficiency, bottlenecks, and opportunities where a CRM can deliver the most substantial improvements. Document these findings meticulously.

- Detailed Requirements Definition: Based on the assessment, create a detailed list of the specific functionalities and capabilities your CRM must possess. Prioritize features based on their impact on operational efficiency, profitability, and customer satisfaction. Involve stakeholders across different departments to ensure a holistic perspective.

- Thorough Vendor Research and Comparison: Research and compare different CRM vendors who specialize in providing solutions for the manufacturing industry. Evaluate their features, pricing models, customer support reputation, industry experience, and integration capabilities. Pay attention to case studies and testimonials from existing clients in similar industries.

- Rigorous Testing and Evaluation: Before committing to a particular CRM, request a trial period or a pilot implementation. This allows you to test the system in a real-world environment, simulating your actual workflows and data volumes. Involve key users from different departments to gather comprehensive feedback on usability, functionality, and integration.

- Seamless Implementation and Comprehensive Training: Once you've chosen a CRM, ensure a smooth and well-planned implementation process. Provide comprehensive training to your staff to maximize user adoption and ensure the system's effective integration into your operations. Ongoing support and user training are crucial for long-term success.

💡 Pro Tip: Don't underestimate the critical importance of robust customer support. Choose a vendor that offers responsive, reliable assistance, comprehensive documentation, and proactive support to address any issues promptly. Consider the vendor's track record in providing timely and effective support to their clients.

Frequently Asked Questions (FAQ)

What are the key benefits of using a CRM for manufacturing?

A CRM tailored for the manufacturing sector offers a multitude of significant benefits, encompassing:

- Improved Customer Relationship Management (CRM): Enhanced communication, personalized interactions, and proactive issue resolution lead to increased customer satisfaction and loyalty.

- Streamlined Order Processing: Automated workflows, reduced manual data entry, and faster order fulfillment lead to improved operational efficiency.

- Enhanced Inventory Management: Real-time visibility into inventory levels, minimized stockouts, and optimized inventory levels contribute to reduced costs and improved production planning.

- Optimized Production Scheduling: Improved scheduling capabilities, real-time monitoring of production progress, and efficient resource allocation lead to increased productivity and on-time delivery.

- Better Data Analysis for Informed Decision-Making: Access to real-time data, comprehensive reporting, and actionable insights facilitate data-driven decisions, leading to better strategic planning and improved operational efficiency.

- Increased Efficiency and Reduced Costs: Streamlined processes, minimized errors, and optimized resource allocation contribute to overall cost reduction and increased profitability.

Conclusion

Selecting the right CRM for your manufacturing operation is a strategic decision with far-reaching implications for your business's success. By meticulously evaluating your specific needs, thoroughly researching the available options, and following a structured implementation process, you can leverage the power of a CRM to optimize your operations, strengthen customer relationships, and drive sustainable growth. Investing in the right CRM is not simply an expense; it's an investment in the future competitiveness and profitability of your manufacturing enterprise. Choose wisely, and reap the rewards of a well-integrated and effective system.

0 Response to "Choosing the Right CRM for Manufacturing: A Comprehensive Guide"

Post a Comment